"Moose Kitty" (moosekitty)

"Moose Kitty" (moosekitty)

05/16/2014 at 15:33 • Filed to: None

0

0

24

24

"Moose Kitty" (moosekitty)

"Moose Kitty" (moosekitty)

05/16/2014 at 15:33 • Filed to: None |  0 0

|  24 24 |

So I've run some numbers and looked over building materials I'd plan on using, and I'd like some input from you guys(and girls) out there that care to put in two cents.

To start off, NUMBERS. For now just the simple stuff since the build materials are what i really want to talk about:

-Engine Displace: 134 cubic inches (2.2L)

-Bore/stroke: 4:1

-Bore: 7.5 in

-Stroke: 1.56 in

-Compression ratio: 15:1

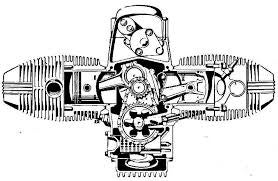

Most of those sound outrageous I know, but hey go big or go home (plus I'm still changing the numbers to make them more reasonable). For those that don't know this engine is a Flat Twin with two variable geometry turbos (one per cylinder) and was water cooled. For the full description there's the link below.

!!! UNKNOWN CONTENT TYPE !!!

Most of the engine was aluminum to save weight, but i'm making some addition and revisions. The pistons would be a beryllium-aluminum blend making it a third of the weight of a regular aluminum piston. The headers and exhaust manifolds would be titanium. The crank would be Light weight, CNC machined, use aerowing counterweights, and be nitrite hardened. Along with the stratified fuel injection there would be dual spark plugs (since the piston is so large and wouldn't have as clean a burn). The intake piping would be carbon fiber reinforced with Kevlar. Each turbo would have a separate intercooler. The radiator would have a fan clutch still to aid in cooling. It would still run around 9000 rpms, but i might push it a bit higher.

These edits are for two reasons: 1) the original was a lot like the bmw r100rs engine 2) it's a racing engine and needed better materials and to be lighter to run at the levels I'd be asking of it.

*What do you guys think. Im open to anything. I am planning on building this design, but slowly and after i get a solid design that has a low chance of immediately blowing up and wasting a bunch of money.

Party-vi

> Moose Kitty

Party-vi

> Moose Kitty

05/16/2014 at 15:47 |

|

15:1 with turbos, eh? Seems like a lot.

Reigntastic

> Party-vi

Reigntastic

> Party-vi

05/16/2014 at 16:00 |

|

Rod through block, calling it now.

Moose Kitty

> Party-vi

Moose Kitty

> Party-vi

05/16/2014 at 16:04 |

|

Meh mostly since the piston is 7 inches though I don't really plan on having it that high.

promoted by the color red

> Moose Kitty

promoted by the color red

> Moose Kitty

05/16/2014 at 16:05 |

|

Titanium is not only expensive but difficult to machine. However, 3D printing in titanium powders is promising.

Touching upon what I said yesterday about fatigue, it may be wise to trade a few grams for added longevity, unless you want to tear-down after every race. Again, you need to consider detonation and lubrication. It might be less of an issue with racing fuel, but with two turbos, high compression ratios, and 9000 rpm it could get ugly fast.

Check out the Honda NR engine for dual spark-plug implementation. It's a V-4 bike engine made by cutting out the space between the cylinders in a V-8 and conjoining the pistons. That said, the piston face can be manipulated along with other smart combustion chamber designs (e.g. direct injection with piston bowl) into a better swirl, producing a better "burn", so dual ignition might be unnecessary.

Edit: You are not going to be building this engine without an F1-sized budget or workshop.

Money Hustard

> Moose Kitty

Money Hustard

> Moose Kitty

05/16/2014 at 16:06 |

|

So, you're going to make a one-off engine with exotic materials on par with a F1 car's engine? Good luck with that.

Not sure why someone would do this.

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Moose Kitty

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Moose Kitty

05/16/2014 at 16:09 |

|

Well, i think this will be quite hard to mass produce, right?

Let's lift off a turbo from CLA45 AMG for moar compression.

*CLA45 use a 26psi Turbo.

promoted by the color red

> Moose Kitty

promoted by the color red

> Moose Kitty

05/16/2014 at 16:12 |

|

15:1 is very high for a petrol engine.

Moose Kitty

> promoted by the color red

Moose Kitty

> promoted by the color red

05/16/2014 at 16:31 |

|

The titanium is more a wish if anything. Your right in the fact that I wouldn't want to rebuild the engine after every race so i'll make revisions there. Thanks for the the ideas on the injection too.

Budget wise the three most expensive pieces would be the titanium, the pistons, and the CF/Kevlar mostly. The rest i've got covered through multiple sources (discounts and unused favors).

Moose Kitty

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

Moose Kitty

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

05/16/2014 at 16:34 |

|

nice idea using the CLA turbos didn't think of that, though it would be a one off engine without the funds for development and in production.

Moose Kitty

> promoted by the color red

Moose Kitty

> promoted by the color red

05/16/2014 at 16:35 |

|

I know though i'm planning on toning it down. The reason why it's so high is because the piston diameter is 7 inches.

Moose Kitty

> Money Hustard

Moose Kitty

> Money Hustard

05/16/2014 at 16:41 |

|

Mostly because why the fuck not. I'm planning on using the engine in the Pikes Peak and Monaco hillclimbs here in Colorado. Starting the engine off I wouldn't be using titanium nor variable geometry turbos. The pistons would still be used though. maybe not the CF/kevlar either until later on.

John Bulzacchelli

> Moose Kitty

John Bulzacchelli

> Moose Kitty

05/16/2014 at 16:46 |

|

Is this a theoretical exercise? If you are planning on actually trying to build something like this you might need to rethink a few things..

1- without a balance shaft, an opposed twin will rattle itself to death at high rpm. Even though the forces are balanced per each cylinder, they are offset. This results in a moment or torque within the crank, and the engine will "wobble"

2- Short stroke, large bore is great for air flow (you can fit larger valves in the head) , but a large bore also takes longer to burn its fuel, which limits RPM. I believe the new Ducati is one of the first modern engines with a bore-stroke ratio over 2.0... Your proposed 4.0 is going to cause you some major issues, especially if you want to rev to 9k rpm. A 7.5 inch bore is just..huge. Even if it spun to 9k rpm, how would the fuel burn fast enough across a chamber of that size?

3-The components would be MASSIVE and heavy - how do you hold the engine together?

4- A large bore is more prone to spark knock. I would be impressed if an engine with that bore & stroke would run without knock around 6.0:1 compression ratio. 15.0:1 is just WAY too high - you are entering diesel territory.

5-VGT turbos are cool - i like it. However, with a large twin set up they will respond better as a single large turbo. An engine does not flow gas smoothly - it pulses. Instead of one massive "pulse" every 720 crank degrees, share the exhaust system and get one pulse every 360 degrees. The turbo will be uncontrollable on one cylinder, as it will be accelerating, decelerating every power stroke.

6- I see you want to use beryllium alloyed pistons...that is some DEADLY stuff!

*My advice if you actually want to make something more realistic: Add more cylinders or reduce displacement. A 2.2L twin is HUGE. Reduce the bore & stroke down to at least 2.0. Drop compression ratio down. Focus on materials which you can actually afford to have build, and utilize one turbo instead of 2!

michael bleggi

> Moose Kitty

michael bleggi

> Moose Kitty

05/16/2014 at 16:53 |

|

With only two cylinders, each cylinder spinning a turbo is just not going to be smooth... why not go one, one huge one, especially since you're going to use variable geometry? what type of variable geometry?

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Moose Kitty

Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

> Moose Kitty

05/16/2014 at 16:58 |

|

aaa, just like my automation engine.

I once made a fully tuned 2 litre inline 4, with 284hp Naturally-Aspirated horses.

I guess you should try automation.

briannutter1

> Moose Kitty

briannutter1

> Moose Kitty

05/16/2014 at 17:09 |

|

You'll need to set the bore off of a readily available performance ring set. 5.080 is commonly used in 5.3 bore space mountain motors. Look for off the shelf bearing availability as well when deciding journal sizes. No one is going to machine you a berylium anything as it's pretty toxic, so you'll have to do it yourself or have your prototype parts done in aluminum.

I didn't see any earlier posts about 4v head or what. If it is, you need to look at the compression calculation. A realistic 80cc chamber minimum for that bore size and resulting dome and valve pockets. You'll find the stroke is too short to hit a reasonable c.r. number. You may want to consider a 5.080 bore and 3" stroke if you're stuck at that displacement target. A 4" stroke would generate even more compression for any given dome rise and piston speed isn't an issue if you are satisfied with 10k rpm. The rpm achieved is really just a given piston speed that uses up a cylinder heads available airflow. So like a 4" stroke turning 10k rpm uses up the same air as a 3" stroke turning 13,250 resulting in nearly the same power (everything else being equal) at the two different power peaks. Of course torque is mostly dependent on displacement. Valvestrain at 13,250 are going to be a little taxed, but 10k should be possible guessing a 2.050 intake valve if 4v head. (also nice because of available titanium valve forgings).

Scaling up a Honda k20 head would remove a lot of your headaches. You'll have to use the valve drop numbers (valve margins in relation to cylinder head deck, cam lift at 10 degree btdc exhaust and 10 atdc intake to know where the valves will be in space when the piston is generally closest to them to determine net valve pocket depths...then the resulting dome height becomes a function of what other voids of the chamber need to be filled without valve pockets that shroud the valve's airflow. All this leads to what you'll be able to generate for compression.

briannutter1

> briannutter1

briannutter1

> briannutter1

05/16/2014 at 17:29 |

|

Also, take a look at the vance and hines NHRA pro stock Harley Davidsons. V-twins at 350 -ish horsepower, 160ci, and 10k rpm

Moose Kitty

> briannutter1

Moose Kitty

> briannutter1

05/16/2014 at 18:38 |

|

Wow thank you...that actually fixed a lot of issues I had with the current design.

Moose Kitty

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

Moose Kitty

> Aya, Almost Has A Cosmo With Toyota Engine Owned by a BMW.

05/16/2014 at 18:40 |

|

I have it, but don't alawys have access. It'll log me off randomly from time to time causing all that work to go down the drain.

Moose Kitty

> michael bleggi

Moose Kitty

> michael bleggi

05/16/2014 at 18:44 |

|

A variable nozzle turbine similar to the one Volvo had on their turbo diesel engine.

Moose Kitty

> John Bulzacchelli

Moose Kitty

> John Bulzacchelli

05/16/2014 at 19:05 |

|

Thanks most of the engine is like the beginnings of a ball of yarn. It's a huge mess and it's becoming more ordered with every revision. Thanks for the input it's really helpful. I am switching to a single turbo and making the engine smaller. These numbers were more testing my ability to calculate everything, and it got kind of out of hand. Plus I messed up between CC and CID at first with some of the measurements, and i think it pushed it to these numbers too.

John Bulzacchelli

> Moose Kitty

John Bulzacchelli

> Moose Kitty

05/16/2014 at 19:19 |

|

If you want to learn some more about engine design I can email you some powerpoints that should help you. I also recommend getting a good book on engine design such as http://www.amazon.com/Introduction-I…

!!! UNKNOWN CONTENT TYPE !!!

BrianNutter

> Moose Kitty

BrianNutter

> Moose Kitty

05/16/2014 at 21:37 |

|

Let me know how it goes and i can help you with finding the right people to build parts.

Moose Kitty

> BrianNutter

Moose Kitty

> BrianNutter

05/17/2014 at 02:15 |

|

Thanks

Moose Kitty

> John Bulzacchelli

Moose Kitty

> John Bulzacchelli

05/17/2014 at 02:18 |

|

Thanks man I need all the help possible to even attempt to make an engine in the first place.